Ultimate Solution For Your Undercarriage

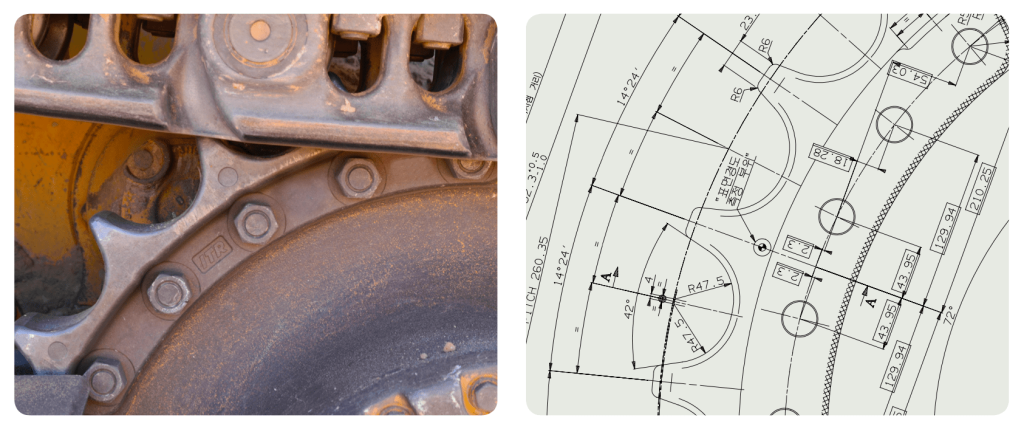

Track Chains

Track Chains

Improved design of the track joints for lubrication retention. Robust components design to avoid breakage and cracking. Components engineered for high impact applications.

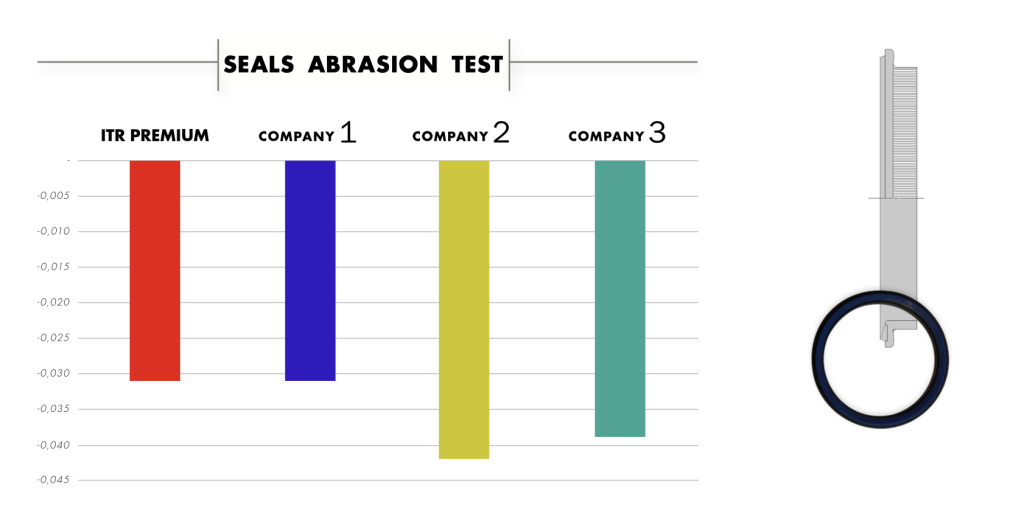

New SEAL GROUPS have been engineered in order to meet the highest quality standards and perform in Heavy-duty applications. The shape of the seals and the material composition guarantee the best oil retention and lubrication between pin and bushing.

The new SYNTHETIC OIL used for new PREMIUM TLA’s is in accordance with API Service Classification GL5. The high viscosity index and additional extreme pressure characteristics of the synthetic oil guarantee working conditions with temperatures ranging from -35° C to +50°C (or from -31°F to +131°F).

New ITR LOCK RING (PPR) provides a mechanical lock between the pin and the link in order to reduce the end-play movements and to control seal compression which enhances working conditions and wear life of pins and bushings.

The new ITR PLUG is composed by a rubber stopper and a plastic plug.

CARBURIZEDBUSHINGcasedepthhasbeenconsistently increased in order to ensure maximum wear life.

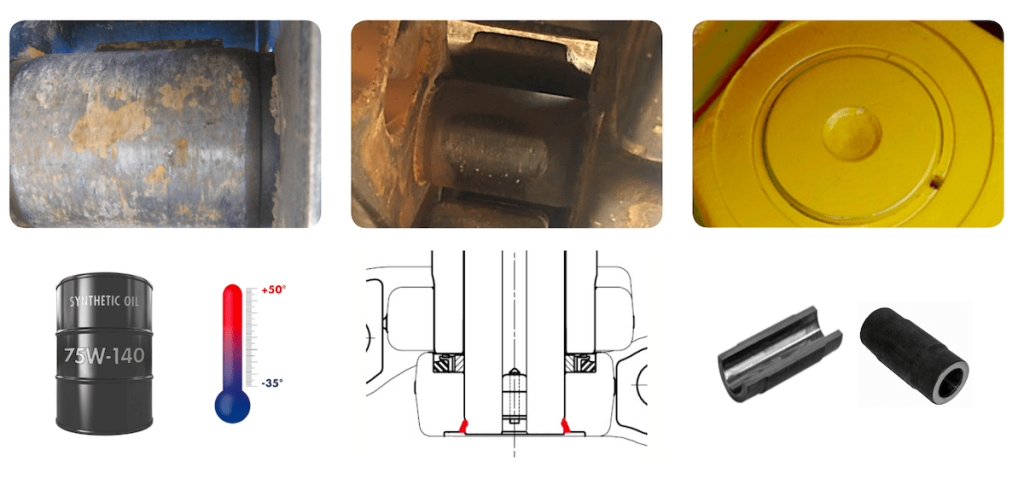

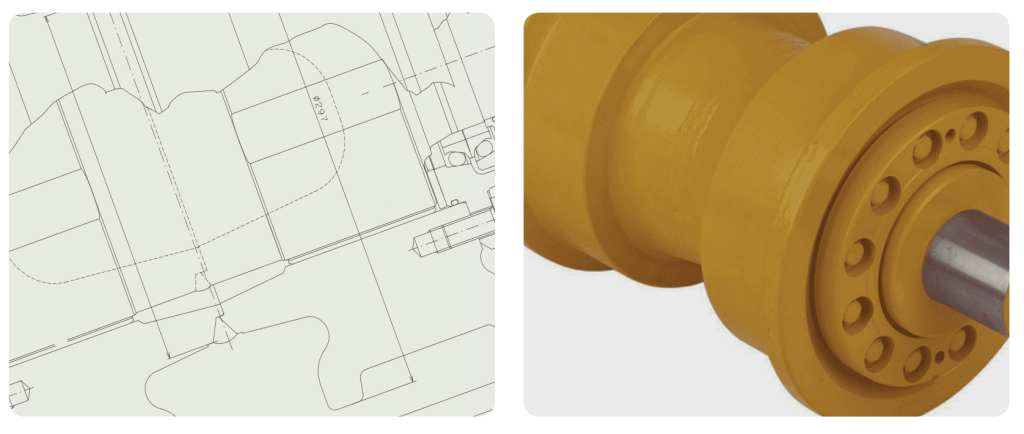

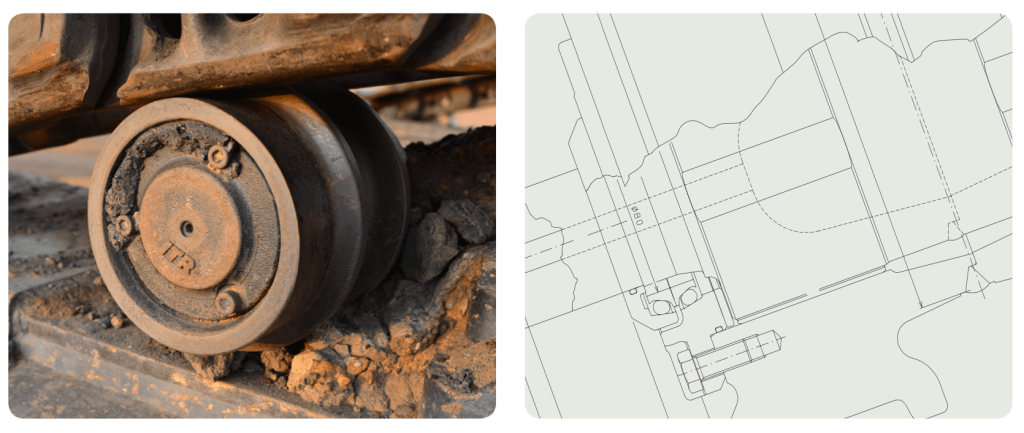

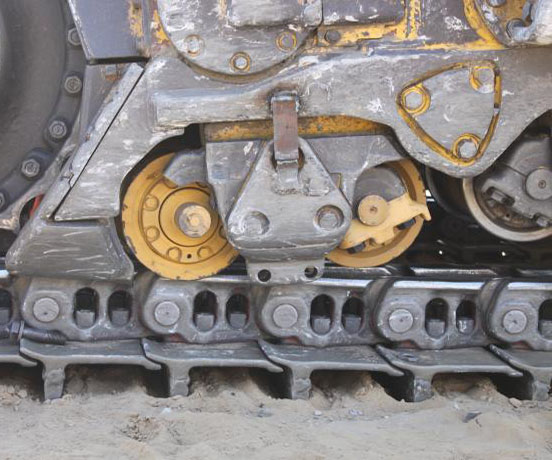

Track & Carrier Rollers

Track & Carrier Rollers

ITR Premium rollers provide excellent performance in demanding environments.

ITR Premium rollers have been specifically conceived, designed and manufactured for mining, quarrying and heavy-duty applications.

Track rollers feature highly-strengthened steel and a reinforced structure to reduce wear and absorb shocks and impacts.

Single flanged, double flanged, as well as carrier rollers, forged from selected and certified boron steel, are through-hardened via differential quenching or through-hardening for extended wear life and extreme resistance to fatigue, stress and impact.

ITR Premium rollers are Lifetime lubricated as a result of use of top-class seals, extensive oil capacity and re-engineered internal flow for uniform and constant lubrication.

ITR Seals, expressly conceived to be used in severe applications, feature excellent performances up to -40°C.

Internal components such as bushings, collars and shafts are designed, produced and tested in the groups facilities to guarantee an accurate fit as well as thorough and consistent lubrication for the best internal lifespan.

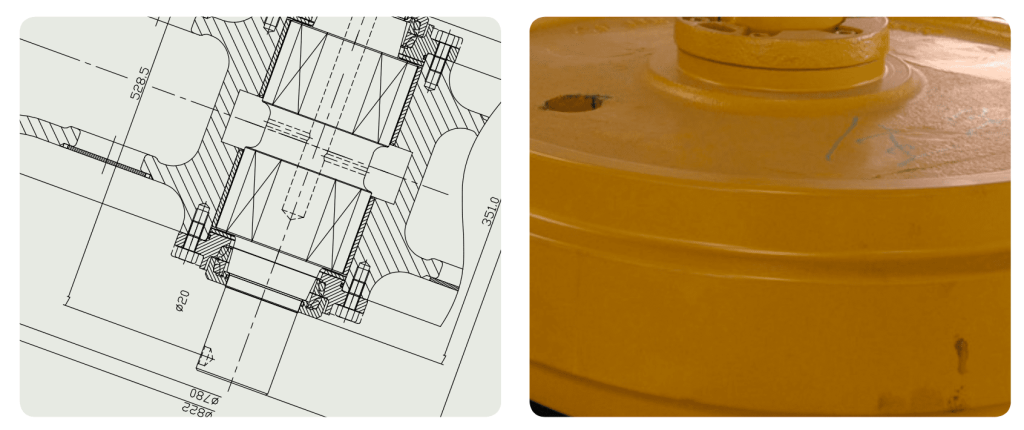

Idlers

Idlers

ITR Premium Idlers are manufactured to provide excellent wear resistance.

ITR Premium Idlers are manufactured through casting a complete range of solid and drum-types, following the application requirements.

All internal components are designed, produced and tested in the groups facilities to guarantee an accurate fit, as well as, the highest reliability and the best lifespan.

Extended wear resistance is assured by specific heat-treatments in order to harden the contacting surfaces. ITR Seals are expressly engineered for heavy-duty applications featuring excellent performances in a temperature range between -40°C and +50°C.

Segment Groups

Segment Groups

ITR Premium segments are the result of the precise forging of excellent boron steel.

ITR Premium segment groups are purposely designed to service extreme and severe working conditions in highly abrasive and impact job-sites.

ITR segment groups are the perfect match for Premium Track chains in order to reduce the wear on bushings, maximizing the lifespan.

Surface and core hardness provides longer wear life and resistance to bending and breakage especially in tough applications.

Accurate design and machining of the assembling areas guarantee the finest performance during machine operations.